Indirect Heaters

Indirect Heaters

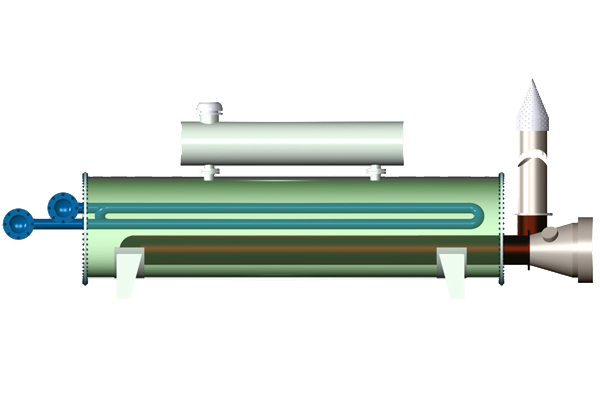

PESCO Indirect Heaters Are Specifically Designed to Heat Gases or Liquids Safely Over a Wide Range of Pressure and Temperatures

As with all PESCO designed equipment, temperature controls and other controls, parts, and accessories are carefully selected for dependable and trouble-free operation. Fuel gas preheat coils are incorporated in the heater to assure a dry fuel gas and prevent fuel line freeze-up when large pressure reductions are required across the fuel gas regulator. A wide selection of accessories is available for various field applications, including adjustable chokes, low level switches, temperature switches, programmable controllers (PLC’s), alarms, etc. Low-noise designs are available.

Typical Applications of Oilfield Filtration Units

- Upstream of glycol dehydrators for removal of compressor lube oil and solid contaminants

- Upstream of compressors to remove solid contaminants and liquids

- In a glycol system to remove solid contaminants and hydrocarbons

- Downstream of glycol absorbers to recover entrained glycol mist

- Upstream of liquid and gas metering devices to prevent plugging and abrasion

Features and Benefits

- Combustible fluids are heated in a flow coil by the hot water bath, completely isolated from the firebox.

- The firebox is always immersed in clean liquid, resulting in long life, and elimination of coking and burnout problems. A clean metal surface rapidly transfers the firebox heat to the water bath.

- A wide range of interchangeable flow coils is available for each size of heater, which allows for easy selection of the proper coil arrangement to satisfy heat transfer area and pressure drop requirements.

- A wide range of standard firebox ratings is available from 100,000 BTU/hour to 4,000,000 BTU/hour.

- Burner and pilot light assemblies are designed to match the firebox capacity and provide safe, dependable, and efficient operation under varying loads and adverse weather.

USEFUL LINKS

© 2024

All Rights Reserved | Process Equipment & Service Company (PESCO)