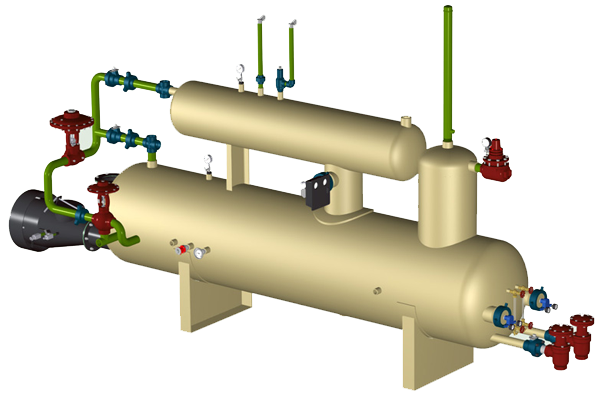

Two-Stage Production Units

The PESCO Two-Stage Separator-Treater Production Unit has a high pressure, 2-phase separator installed on top of a low pressure, 3-phase separator-treater. This unit is sometimes referred to as an HLP.

This unit is designed for wells that:

- Have relatively high shut-in pressure

- Have moderate gas volume

- Have moderate liquids volume

- Have moderately difficult liquids separation

- Produce into a high pressure gas sales line

The high-pressure separator can be either vertical or horizontal, with the liquid section immersed in the low-pressure separator-treater. This combines the advantage of an inlet separator that efficiently separates the gas phase from total liquids, and long residence time for clean separation of the oil and water phases in the low pressure separator. Gas is routed from the high pressure separator to a pipeline and the oil and water mix is dumped to the low pressure side for further separation. The firebox then does double duty: heating the coil, and providing heat to facilitate oil/water separation.

A wide variety of options can be incorporated into the design.

Coils are typically rated for 3000 psig with many combinations of choke and pressure control available. All PESCO equipment is designed and fabricated to meet and exceed our customer’s specifications.

Features & Benefits of Two-Stage Production Units:

- Heating Coil when fitted with thermostatically controlled 3-way valve allows heating all or part of the well-stream.

- Can be configured to 2 or 3-phase separation.

- Minimal heating of the gas stream produces less entrained vapors which allow easier dehydration, usually the next step in preparing the gas for market

- Easily reconfigured to meet changing production conditions

Additional Features

- Pipeline Pump(s)

- Pipeline Pressure Transmitter

- Flow Control with Variable Frequency Drives (VFDs)