PESCO Builds Portable Hydrogen Production Units for BayoTech

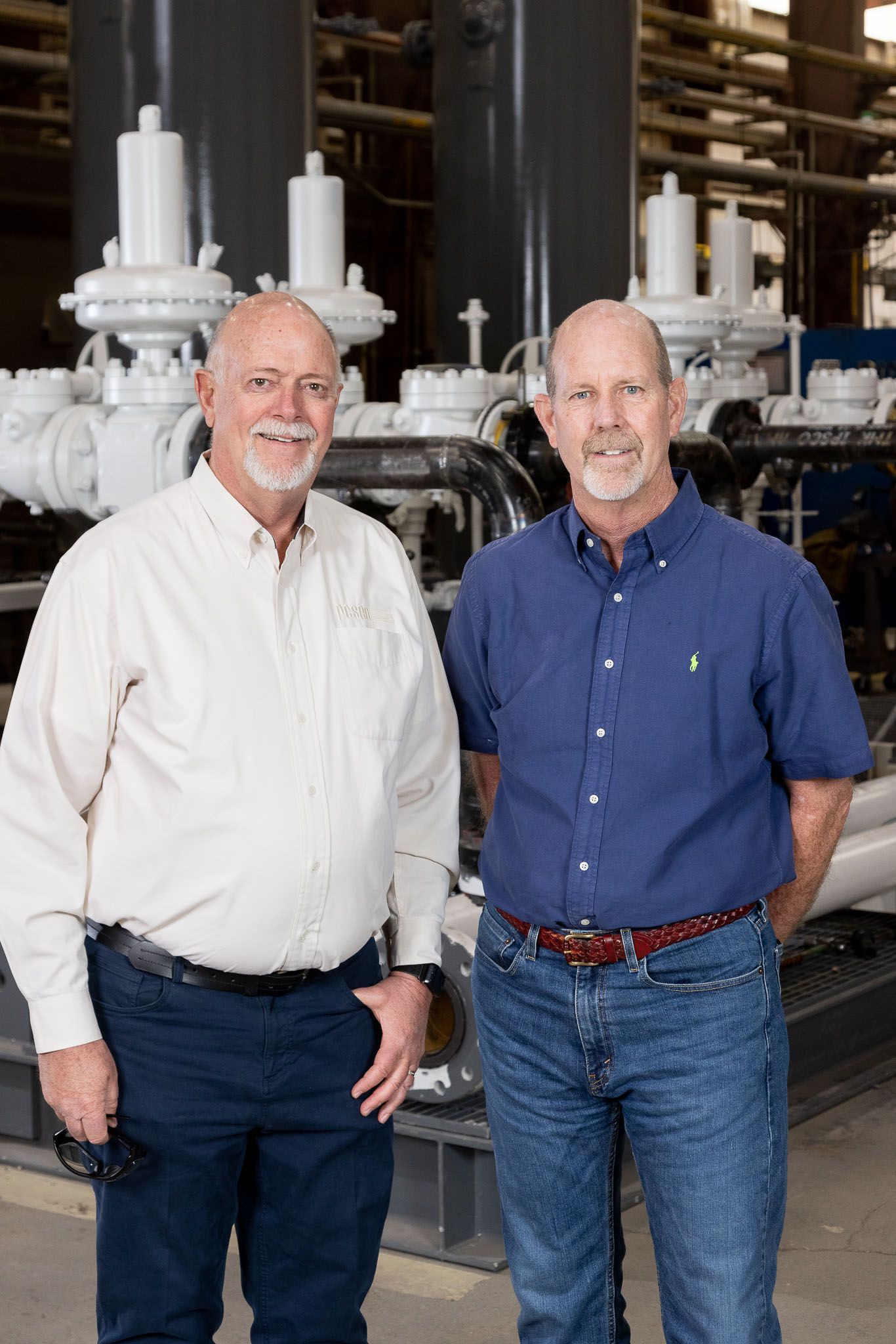

PESCO is an industry leader in process equipment engineering and manufacturing, and Albuquerque-based company BayoTech recognized that when it partnered four years ago with PESCO to build its portable, on-site hydrogen production units.

“We’ve been working with them for four years, building components for their prototype. We’re going to be building the units in the immediate future,” said John Byrom, business development manager for PESCO.

BayoTech’s core technology originally came out of Sandia National Laboratories following more than $50M of research and development. BayoTech’s on-site hydrogen generators reduce or eliminate transportation and storage costs, which result in less energy wasted and a lower carbon footprint than traditional hydrogen production technology and electrolyzer-based systems.

BayoTech chose PESCO to build the skid-mounted hydrogen production units, which are very similar to the units that PESCO manufactures for oil and gas companies.

“This partnership demonstrates PESCO’s ability to work with a company to develop their technology into a full production-ready product,” Byrom said. “It also shows how PESCO is able to use its core competencies of process equipment engineering and design to manufacture beyond oil and gas into the chemical industry and for power generation.”

Byrom said the units are built on large skids that can be picked up and set where needed and then turned on.

“PESCO brings over 50 years of proven experience engineering and manufacturing skid-based equipment for the oil and gas industry”, said BayoTech Chief Operating Officer, Linh Austin. “We’re thrilled to have a partner like PESCO that can provide the manufacturing expertise and scalability required to meet BayoTech’s growing customer demand worldwide.”

BayoTech’s mission is to move hydrogen production closer to demand and make it more affordable and accessible to the companies that want to join the growing hydrogen economy. BayoTech’s high efficiency hydrogen generators are built in modules that can be stacked on a train or placed on a semi and then be shipped anywhere around the world with the purpose of taking local raw materials and turning them into hydrogen.

“There’s equipment piping, control valves, automation, computers, and electronics that PESCO has been working with for many, many years, and those skills translate well to making these chemical reactors,” Byrom said.

The partnership with BayoTech came from PESCO’s reputation of being an industry leader in process equipment technology. A local oil and gas company was familiar with PESCO’s work quality and referred BayoTech to the Farmington-based company to manufacture the product.

“BayoTech’s regional managers came up and met with us,” Byrom said. “We learned about their technology. As they moved forward, we’ve been building different components of their prototype unit.”

Now, PESCO is ready to take that technology and start full production on the portable hydrogen units, according to Byrom, who said, “This unit will be able to use natural gas and water and with those two ingredients be able to generate hydrogen at the site where it is needed.”

Byrom added, “What we’re good at is making things on a skid – on a truck – it’s modular – if you need to make a lot of hydrogen or other chemicals, you can buy a lot of these units and hook them all together.” These modular process equipment units demonstrate what PESCO has been able to build for BayoTech and other industries like it. This is a partnership moving both companies into the future.